In the fast - evolving landscape of augmented reality (AR) technology, every component of AR glasses plays a pivotal role in determining the user experience. Among these components, the frame is not just a supporting structure but a key element that impacts comfort, functionality, and durability. In recent years, magnesium alloy has emerged as a top - choice material for AR glass frames, and Jiakai, a specialized manufacturer in this field, has been making waves with its innovative solutions.

The Rise of Magnesium Alloy in AR Glass Frame Manufacturing

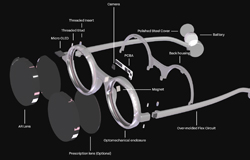

Magnesium alloy, a blend of magnesium with other elements such as aluminum, zinc, and manganese, has unique properties that make it an ideal candidate for AR glass frames. The most prominent advantage is its lightweight nature. AR glasses are designed to be worn for extended periods, and a heavy frame can quickly become a burden. Magnesium alloy frames are significantly lighter compared to traditional materials like stainless steel or even some types of plastics. For example, the density of magnesium alloy is typically around 1.7 - 2.0 g/cm³, which is much lower than that of steel (about 7.8 g/cm³). This lightweight characteristic ensures that users can enjoy a more comfortable and fatigue - free AR experience, whether they are using the glasses for work, entertainment, or navigation.

Magnesium alloy also has excellent heat dissipation properties. AR glasses are equipped with various electronic components that generate heat during operation, such as processors, batteries, and displays. If this heat is not dissipated efficiently, it can lead to performance degradation, reduced battery life, and an uncomfortable user experience. Magnesium alloy frames can effectively transfer heat away from the components, helping to keep the glasses cool and ensuring optimal performance.

In addition, magnesium alloy has good corrosion resistance. Since AR glasses may be used in different environments, including humid or dusty conditions, the ability of the frame material to resist corrosion is vital for long - term use. The alloy forms a thin oxide layer on its surface when exposed to air, which protects it from further corrosion, extending the lifespan of the AR glasses.

Jiakai: A Pioneer in Magnesium Alloy AR Glass Frame Manufacturing

Jiakai has positioned itself as a leading manufacturer dedicated solely to magnesium alloy AR glass frames. Their commitment to this specific niche has allowed them to develop in - depth expertise and a comprehensive understanding of the material and its applications in AR glasses.

One of the key strengths of Jiakai is its advanced manufacturing technology. The company invests heavily in research and development to stay at the forefront of magnesium alloy processing. They use state - of - the - art techniques such as precision casting, forging, and machining to create high - quality frames. For instance, their precision casting process enables the production of frames with complex geometries and tight tolerances, ensuring a perfect fit for the various components of AR glasses. This high - level of manufacturing precision not only enhances the functionality of the frames but also contributes to the overall aesthetics of the AR glasses.

Jiakai also has a team of highly skilled engineers and technicians. These professionals have extensive experience in working with magnesium alloy and are well - versed in the requirements of AR glass frame design. They can collaborate closely with clients to understand their specific needs, whether it's a custom frame design for a new AR product or an improvement on an existing one. Their expertise allows them to offer valuable insights and suggestions during the design phase, helping clients to optimize the performance and appearance of their AR glasses.

Quality control is another area where Jiakai excels. The company has implemented a rigorous quality management system to ensure that every magnesium alloy AR glass frame leaving their factory meets the highest standards. From the selection of raw materials to the final inspection of the finished product, each step of the production process is closely monitored. This attention to quality has earned Jiakai a reputation for reliability among its clients in the AR industry.

Why Collaborate with Jiakai?

In the AR market, where innovation and differentiation are crucial, customization is a key factor. Jiakai understands this well and offers a high degree of customization for magnesium alloy AR glass frames. Whether it's a unique frame shape, a specific color finish, or the integration of special features, Jiakai can work with clients to bring their ideas to life. For example, they can create frames with ergonomic designs tailored to different face shapes, ensuring maximum comfort for users. They also offer a wide range of surface treatments, such as anodizing, powder coating, and polishing, to achieve the desired aesthetic and functional properties. This customization ability allows AR glass manufacturers to create products that stand out in the market and meet the diverse needs of their customers.

Technological Support and Innovation

Jiakai is not just a manufacturer; it is also a partner that provides technological support and drives innovation. The company is constantly exploring new ways to improve the performance of magnesium alloy AR glass frames. They conduct research on new alloy formulations, manufacturing techniques, and surface treatments to enhance the properties of the frames. By collaborating with Jiakai, AR glass manufacturers can benefit from this continuous innovation. For example, Jiakai may develop a new alloy that offers even better heat dissipation or a more lightweight yet stronger frame structure. This access to the latest technological advancements can give AR glass manufacturers a competitive edge in the market.

In today's environmentally conscious world, sustainability is an important consideration. Magnesium alloy is a highly recyclable material, and Jiakai takes this into account in its manufacturing processes. The company has implemented recycling programs for the waste generated during production, reducing the environmental impact. By choosing to collaborate with Jiakai, AR glass manufacturers can contribute to a more sustainable future. Using recyclable magnesium alloy frames also aligns with the growing consumer demand for eco - friendly products, enhancing the brand image of AR glass manufacturers.

The Future of Magnesium Alloy AR Glass Frames

As AR technology continues to advance and penetrate various industries, the demand for high - quality AR glasses will only increase. Magnesium alloy AR glass frames, with their numerous advantages, are expected to play an even more significant role in the future. Jiakai, with its focus on innovation, customization, and quality, is well - positioned to meet this growing demand.

Looking ahead, we can expect to see more advanced magnesium alloy formulations that offer even better performance in terms of weight, strength, and heat dissipation. Jiakai will likely continue to invest in research and development to stay ahead of the curve. The company may also expand its customization options, offering more advanced features and design elements for AR glass frames.

Collaboration with Jiakai will become increasingly valuable for AR glass manufacturers. By working together, they can create AR glasses that are not only technologically advanced but also stylish, comfortable, and sustainable. Whether it's for the consumer market, industrial applications, or the healthcare sector, the combination of magnesium alloy frames and Jiakai's manufacturing expertise will open up new possibilities for the AR industry.

Home

Home admin

admin  May 14,2025

May 14,2025

Jiakai: The Future of AR Eyewear Starts With Premium Magnesium Frames

Jiakai: The Future of AR Eyewear Starts With Premium Magnesium Frames