As a specialized manufacturer focused exclusively on magnesium alloy AR glasses frames, Dongguan Jiakai Precision Metal Products Co., Ltd. has established industry leadership through our deep material expertise and precision manufacturing capabilities. Our magnesium alloy frames represent the optimal solution for AR headset manufacturers seeking to combine lightweight comfort with uncompromising durability.

Advantages of Magnesium Alloy AR glasses Frame

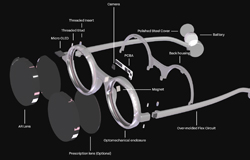

The fundamental advantage of our magnesium alloy frames lies in their exceptional material properties. With a density of just 1.74 g/cm³ - significantly lighter than aluminum or titanium alternatives - our frames enable sleeker, more comfortable AR designs without sacrificing structural integrity. The material's high thermal conductivity actively dissipates heat from processing units, while its natural EMI shielding properties protect sensitive electronics from interference, addressing two critical challenges in AR eyewear development.

Our manufacturing process integrates advanced die-casting technology with precision CNC machining to produce frames with exacting dimensional accuracy. The production begins with high-pressure die casting using 2800T machines capable of achieving ±0.05mm tolerances, followed by meticulous CNC finishing to ensure optical-grade surface quality. Proprietary surface treatments including micro-arc oxidation and PVD coating are then applied to enhance durability, with options for customized finishes to meet specific aesthetic requirements.

Quality assurance is embedded throughout our production workflow, from incoming material inspection to final product verification. We employ coordinate measuring machines (CMM) for dimensional verification, X-ray inspection for internal quality assessment, and rigorous environmental testing to validate performance under real-world conditions. This comprehensive quality system, backed by ISO certification, ensures consistent reliability across production batches.

The applications for our magnesium alloy frames span consumer and professional AR segments. For consumer AR glasses, we produce ultra-lightweight frames as thin as 0.6mm that maintain structural rigidity. Enterprise and industrial applications benefit from our frames' enhanced thermal management and durability, particularly important for devices used in demanding environments. Our ongoing R&D focuses on developing next-generation magnesium alloys with improved strength and corrosion resistance to support future AR innovations.

Home

Home admin

admin  May 09,2025

May 09,2025

Magnesium Alloy AR Glasses Frames: The Ultimate Choice for Next-Generation Eyewear

Magnesium Alloy AR Glasses Frames: The Ultimate Choice for Next-Generation Eyewear