Magnesium Alloys: Redefining Performance Standards for AR Frames

The transition to magnesium alloys represents a quantum leap in AR eyewear technology. As specialists in this transformative material, we've developed proprietary alloy compositions that deliver unprecedented strength-to-weight ratios while maintaining the dimensional stability required for precision optical applications. Our research has demonstrated that properly engineered magnesium frames can reduce overall device weight by up to 40% compared to conventional materials, a critical factor in user adoption and comfort for extended reality applications.

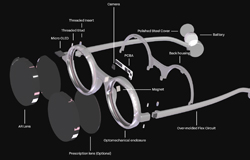

Precision Manufacturing for Demanding AR Applications

Our production methodology combines advanced metallurgical techniques with cutting-edge digital manufacturing systems. The result is a manufacturing ecosystem capable of producing complex frame geometries with micron-level precision, essential for maintaining the optical alignment of waveguide displays and sensor arrays. Through innovative processes like vacuum-assisted high-pressure die casting and computer-controlled aging treatments, we achieve material properties that meet the rigorous demands of both consumer and enterprise AR solutions.

Surface Engineering: The Hidden Technology Behind Durable AR Frames

Beyond the base material properties, our surface treatment technologies provide the invisible performance enhancements that distinguish professional-grade AR eyewear. The multi-stage surface modification process we've developed creates nano-ceramic layers that simultaneously improve wear resistance, reduce glare, and enhance biocompatibility. These treatments are particularly valuable for medical and industrial applications where devices must maintain performance through repeated sterilization cycles or exposure to harsh environments.

Quality Systems Designed for Optical-Grade Components

The transition from traditional eyewear to AR-compatible frames introduces new quality challenges that conventional inspection methods cannot address. Our quality assurance program incorporates 3D optical scanning, coordinate measurement machines, and specialized jigs that verify both mechanical and optical performance parameters. This comprehensive approach ensures that every frame not only meets dimensional specifications but also maintains the precise alignment required for augmented reality applications.

Collaborative Development for Cutting-Edge AR Solutions

Our engineering team operates as an extension of our clients' R&D departments, offering deep expertise in material science, human factors engineering, and production optimization. This collaborative model has yielded numerous innovations, including integrated thermal management features, modular mounting systems, and hybrid material constructions that combine the benefits of AR magnesium with other advanced materials.

The Road Ahead: Emerging Alloy Technologies for Future AR Devices

Looking toward the next wave of AR innovation, we're investing heavily in next-generation alloy development. Our materials science team is currently qualifying new magnesium-based composites that promise even greater weight reductions while introducing novel properties like tunable damping characteristics and enhanced electromagnetic compatibility. These advancements will enable thinner form factors and new functionality in coming AR device generations.

A Trusted Manufacturing Partner for the AR Revolution

In an industry where technological advancements occur at breakneck speed, we provide the manufacturing stability and technical expertise needed to bring visionary AR concepts to market. Our vertically integrated production model gives clients single-source accountability from material formulation to finished component, reducing supply chain complexity while ensuring consistent quality. For companies serious about competing in the premium AR segment, our magnesium alloy AR glasses frames solutions offer a clear competitive advantage in both performance and manufacturability.

Home

Home admin

admin  May 09,2025

May 09,2025

Premium Magnesium Alloy AR Glasses Frames - Engineered for Next-Generation Wearables

Premium Magnesium Alloy AR Glasses Frames - Engineered for Next-Generation Wearables