As augmented reality (AR) technology transitions from niche applications to mainstream adoption, the hardware that delivers these immersive experiences must evolve in tandem. At the forefront of this revolution is Jarkel Casting, a precision engineering specialist that has redefined wearable AR technology through its innovative magnesium alloy frames. These aren't just supports for lenses - they're sophisticated platforms that merge cutting-edge functionality with uncompromising comfort and style, setting a new standard for what AR eyewear can achieve.

The Magnesium Advantage in AR Wearables

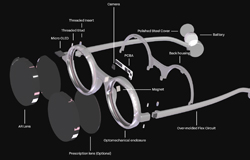

The unique demands of AR glasses frames create engineering challenges that conventional materials struggle to meet. Unlike passive eyewear, AR frames must simultaneously: support delicate optical components, dissipate heat from processors, maintain signal transparency for antennas, and endure constant daily wear - all while remaining lightweight enough for comfort. Jarkel Casting's aerospace-grade magnesium solutions address these challenges through material science innovation. Their proprietary alloys offer an optimal balance of strength-to-weight ratio, electromagnetic neutrality, and thermal conductivity that plastic simply can't match, while avoiding the weight penalties of steel or the cost premiums of titanium.

Precision Engineering for Next-Generation AR

Jarkel Casting's manufacturing process represents a leap forward in wearable tech construction. Using advanced die-casting techniques refined from their aerospace work, they create monocoque frame structures with integrated component bays that protect sensitive electronics while maintaining sleek profiles. The frames feature millimeter-perfect alignment channels for waveguide optics and precision-milled heat sinks that keep processors operating at peak efficiency. Perhaps most impressively, their patented hollow-core construction reduces weight by up to 30% compared to solid magnesium alternatives, achieving durability without burdening the wearer.

From Laboratory to Lifestyle

Understanding that AR glasses must transition from tech demo to daily accessory, Jarkel Casting has invested heavily in human-centric design. Their frames employ ergonomic principles derived from thousands of facial scans, ensuring all-day comfort across diverse physiognomies. The matte anodized finishes resist fingerprints while providing just enough grip for secure positioning. Interchangeable nose pads and temple tips allow personalized fit adjustments, crucial for maintaining the precise optical alignment that AR experiences require. The company offers multiple form factors - from professional minimalist designs to sport-ready wraparound versions - all sharing the same uncompromising technical foundation.

The Sustainable Tech Ecosystem

In an industry often criticized for planned obsolescence, Jarkel Casting builds longevity into their AR platforms. The modular design allows component upgrades without replacing the entire frame, while the magnesium construction withstands years of daily use. Their closed-loop recycling program recovers over 95% of material from end-of-life products, and the manufacturing process now utilizes 60% renewable energy. This commitment to sustainability extends to software partnerships - the frames are designed to be future-proof, compatible with upcoming AR standards and protocols.

Redefining Reality Through Material Innovation

Jarkel Casting's magnesium AR glasses frames represent more than just a hardware innovation - they're enabling the next phase of human-computer interaction. By solving fundamental material challenges, they've created a platform where digital overlays can seamlessly integrate with physical reality without the distractions of bulky hardware or uncomfortable wear. As AR transitions from novelty to necessity in fields ranging from medicine to manufacturing, education to entertainment, the importance of this foundational technology cannot be overstated. The company continues to push boundaries, with prototypes exploring integrated battery solutions and adaptive frame geometries that respond to usage patterns.

In the emerging landscape of spatial computing, Jarkel Casting has positioned itself not just as a component supplier, but as a key enabler of the AR revolution. Their frames don't just hold technology - they elevate it, creating wearable systems that feel less like gadgets and more like natural extensions of human capability. As the line between physical and digital continues to blur, the importance of such thoughtfully engineered interfaces will only grow, making Jarkel Casting's innovations increasingly central to our technological future.

Home

Home admin

admin  May 06,2025

May 06,2025

The Future of AR Eyewear: How Jarkel Casting is Revolutionizing Smart Glasses with Premium Magnesium Frames

The Future of AR Eyewear: How Jarkel Casting is Revolutionizing Smart Glasses with Premium Magnesium Frames