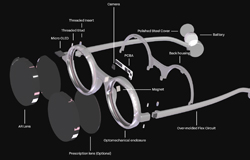

The augmented reality (AR) industry is rapidly evolving, and at the heart of this transformation lies the need for durable, lightweight, and high-performance AR glasses frames. Jarkel Casting, a leading manufacturer specializing in precision magnesium casting, has emerged as a key supplier for next-generation AR eyewear. With decades of expertise in metal casting and a state-of-the-art production facility, the company delivers frames that perfectly balance advanced functionality, ergonomic comfort, and sleek aesthetics. Unlike traditional plastic or titanium frames, Jarkel’s magnesium alloy solutions provide the ideal combination of strength, heat dissipation, and electromagnetic compatibility—critical factors for AR glasses that integrate complex optical systems, sensors, and processors.

Jarkel Casting’s manufacturing facility is equipped with cutting-edge die-casting and CNC machining capabilities, ensuring micron-level precision in every frame produced. The company’s vertically integrated production process allows for strict quality control at every stage, from raw material selection to final finishing. Their magnesium AR frames are crafted using aerospace-grade alloys, which undergo rigorous testing for durability, weight distribution, and thermal management. This is particularly crucial for AR glasses, as overheating can impair performance and user comfort. Additionally, Jarkel’s proprietary hollow-core construction techniques reduce weight without compromising structural integrity, making their frames ideal for extended wear in professional, industrial, and consumer applications.

Beyond technical excellence, Jarkel Casting places a strong emphasis on customization and scalability. Recognizing that AR glasses frames serve diverse markets—from enterprise and healthcare to gaming and everyday smart wear—the company offers tailored solutions that meet specific design and functional requirements. Their engineering team collaborates closely with AR hardware developers to optimize frame designs for seamless integration of waveguide displays, depth sensors, and battery modules. Furthermore, Jarkel’s commitment to sustainability is evident in their eco-friendly manufacturing practices, including energy-efficient production lines and a closed-loop magnesium recycling system. As the demand for AR glasses grows, Jarkel Casting is poised to remain a trusted partner for brands seeking high-performance, future-proof frames that enhance both user experience and product longevity.

The rise of AR technology is reshaping how we interact with digital content, and the hardware supporting this revolution must be equally innovative. Jarkel Casting’s expertise in precision magnesium manufacturing positions them at the forefront of this industry, providing frames that are not just functional but also stylish and sustainable. With a proven track record in delivering high-quality casting solutions across industries, the company is well-equipped to meet the evolving demands of AR eyewear. Whether for enterprise AR headsets, consumer smart glasses, or specialized medical visors, Jarkel’s magnesium frames offer the perfect blend of technology and design, ensuring that the next generation of AR devices is both powerful and wearable. As more industries adopt AR solutions, Jarkel Casting’s role as a reliable, forward-thinking supplier will only become more critical in shaping the future of smart eyewear.

Home

Home admin

admin  May 06,2025

May 06,2025

Why Magnesium Alloy is the Best Choice for AR Smart Glasses Frames

Why Magnesium Alloy is the Best Choice for AR Smart Glasses Frames