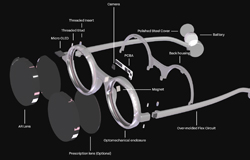

As augmented reality (AR) technology becomes more sophisticated, manufacturers face increasing pressure to develop comfortable, high-performance smart glasses. One of the biggest challenges lies in the frame material - it must be incredibly lightweight yet durable enough to house sensitive electronics. While traditional materials like plastic and aluminum have been used, magnesium alloy emerges as the superior solution, offering an unbeatable combination of properties that make it ideal for next-generation AR eyewear.

Unparalleled Weight Advantage

Magnesium alloy's most compelling advantage is its exceptional lightness. As the lightest structural metal available, it's:

- 30% lighter than aluminum

- 50% lighter than titanium

- Nearly as light as high-end plastics

This weight reduction is crucial for AR glasses, where every gram matters for user comfort during extended wear. Unlike plastic frames that need reinforcement, magnesium maintains structural integrity at minimal weight.

Superior Strength and Durability

- Higher strength-to-weight ratio than aluminum

- Better impact resistance than plastic

- Maintains shape under stress better than competing materials

This combination means AR glasses can withstand daily wear while protecting delicate internal electronics. The material's natural rigidity also helps maintain precise optical alignment - critical for AR applications.

Enhanced Thermal Management

AR glasses generate significant heat from their processors and displays. Magnesium excels at thermal management:

- Thermal conductivity 3-4 times better than plastic

- Efficient heat dissipation protects sensitive components

- Prevents uncomfortable warmth against the skin

This thermal performance extends device lifespan and improves user comfort during prolonged use.

Electromagnetic Shielding Properties

- Protects sensitive AR electronics from interference

- Reduces radiation exposure to the user

- Improves signal reliability for wireless functions

This built-in shielding is superior to plastic frames that require additional coatings or treatments.

Manufacturing Advantages

- Excellent castability for complex frame designs

- High precision machining capabilities

- Good surface finish options

- Compatibility with various coating technologies

These properties allow manufacturers to create sleek, sophisticated designs that would be difficult or impossible with other materials.

Magnesium alloy represents the ideal balance of lightness, strength, and functionality for AR smart glasses frames. Its unique combination of properties solves multiple design challenges simultaneously, offering benefits that no single alternative material can match. As AR technology advances toward mainstream adoption, magnesium will undoubtedly play an increasingly important role in creating comfortable, high-performance smart glasses that people will want to wear all day.

For manufacturers looking to push the boundaries of AR eyewear design, magnesium alloy isn't just an option - it's becoming the standard for premium AR glasses frames. Its superior performance characteristics make it the material best positioned to meet the evolving demands of both consumers and technology in this exciting field.

As major tech brands increasingly adopt magnesium alloy for AR eyewear, partnering with a proven manufacturer ensures superior product quality while accelerating time-to-market. For OEMs seeking cutting-edge AR frame solutions, magnesium alloy manufacturers such as Jarkel Casting offer the technical capabilities and industry experience needed to enable the next generation of smart glasses.

Home

Home admin

admin  May 07,2025

May 07,2025

Your Premier Partner for AR Magnesium Alloy Eyewear Frames

Your Premier Partner for AR Magnesium Alloy Eyewear Frames